Sustainable processing of foundry wastewater at AUDI AG on the site in Münchsmünster

In November 2013, AUDI AG opened its new production facilities in Münchsmünster. In the Industrial Park in Münchsmünster, located approximately 30 kilometres to the east of the main plant, an Audi competence centre was created for the production of bodywork structural parts made of die-cast aluminium, hot and cold formed pressed parts, as well as chassis components. During production, various types of industrial wastewater is produced which may not be discharged into the public sewage system. Even during the plant planning, a concept was devised for the sustainable and efficient processing of this wastewater. Dr. Lindemann

Consulting executed this planning

Vacuum distillation – Why?

During the die-casting process, release agents are essential auxiliary materials to prevent malfunctions during the production process and to ensure the quality of the manufactured parts. The consumed release agents, either dissolved or emulsified in the industrial wastewater from the foundry, may not be discharged into the public sewage system. According to Dr. Lindemann at Dr. Lindemann Consulting, “This wastewater is best processed using vacuum distillation systems.” “In the meantime, they have proved themselves to be the safest and most efficient method on the market.” In addition to efficiency with regard to operating costs, Audi also placed great emphasis on process safety and sustainability. They wanted to create a simple, uncomplicated system that would not divert attention from the foundry’s main task of production.

Reliable and safe process

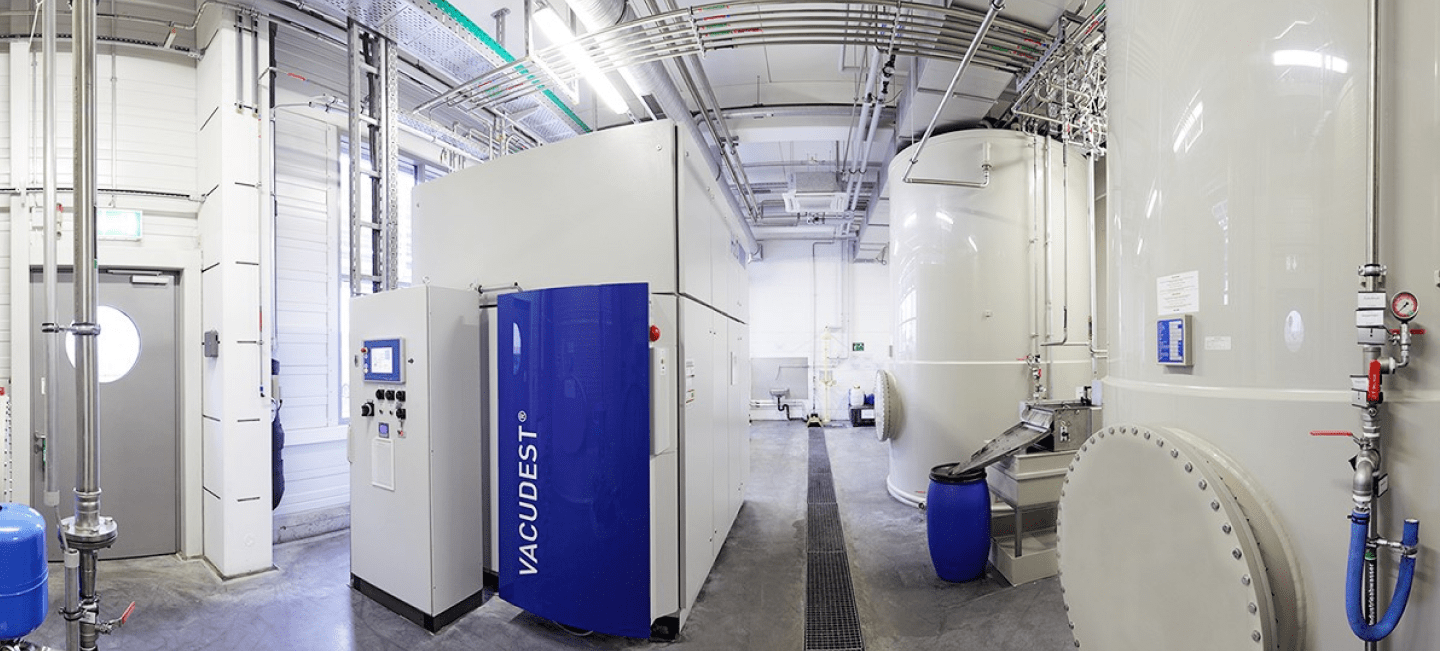

H2O GmbH from Steinen, a leading manufacturer of vacuum distillation systems, focused intensively on AUDI AG’s requirements and, as a result, developed a customised system.

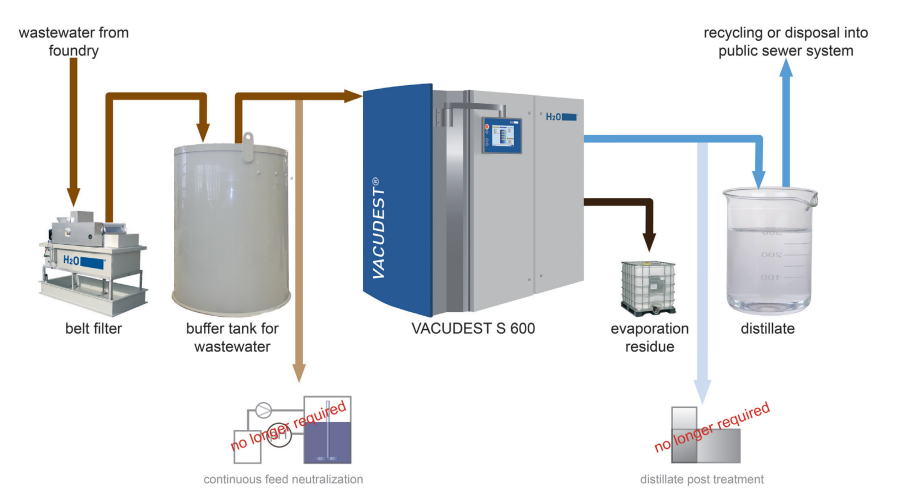

Wastewater from die-cast aluminium often has a pH value of less than 7 and is therefore slightly corrosive. In order to prevent damage to the evaporator and to comply with the statutory effluent limit values for the processed water, the foundry effluent must first of all be neutralised when using conventional evaporators. H2O GmbH’s Destcontrol technology measures the pH value in the distillate and meters lye directly into the evaporator to modify the pH value. As such, a continuous neutralisation before the evaporator is no longer required.

The distillate from conventional evaporators may not be discharged directly to the sewage system since the limit value for hydrocarbons would not be complied with. The processed water must undergo post-treatment using adsorbents, active carbon filters or membrane systems to permit discharging into the network. That’s why H2O GmbH has developed the pioneering Clearcat condensation system. This patented technology, built into the evaporator, ensures that the distillate reliably meets the discharge limit value for hydrocarbons. Therefore another process step can be left out completely.

A redundantly designed analysis system continuously monitors and records the most important limit values in the purified water and therefore ensures that no polluted water is discharged to the sewage system.

First practical experience

The project was given the green light in July 2013. Assembly had already begun in September. The first practical tests with wastewater from the foundry took place after three months into the construction works in December 2013. Within the framework of a planned increase in production in the foundry, the system was charged to full load by 2016. The results to date confirm the decision of opting for the sophisticated VACUDEST vacuum distillation system developed by H2O GmbH. All of the promised values with regard to operating costs and the quality of the processed water have been achieved.

Vacuum distillation: Simple principle Efficient effect

The process is based on the simple principle of material separation according to boiling point differences. The foundry wastewater is evaporated. All substances which have a higher boiling point than water remain in the evaporation residue. This includes heavy metals, salts, oils and greases as well and, of course, the release agents. Given that the proportion of water is evaporated, the residue volume from the evaporation is reduced to 0.5 to 2% of the original wastewater volume. This evaporation residue is then disposed of at a fraction of the original costs by a certified specialist company. As a result of the reduction in the disposal costs, the investment for the processing system usually pays for itself in less than 2 years

95% energy efficiency ensures the lowest operating costs

Although stigmatised in the past as being energy guzzlers, modern evaporators are now very economical. The energy generated from the steam created is returned to the vacuum distillation system. As such, no external heating energy is required. This is how energy efficiency has, in the meantime, reached 95% compared to atmospheric evaporation. Operating costs for evaporators are therefore far more economical than for other processing procedures, even in

light of rising energy prices